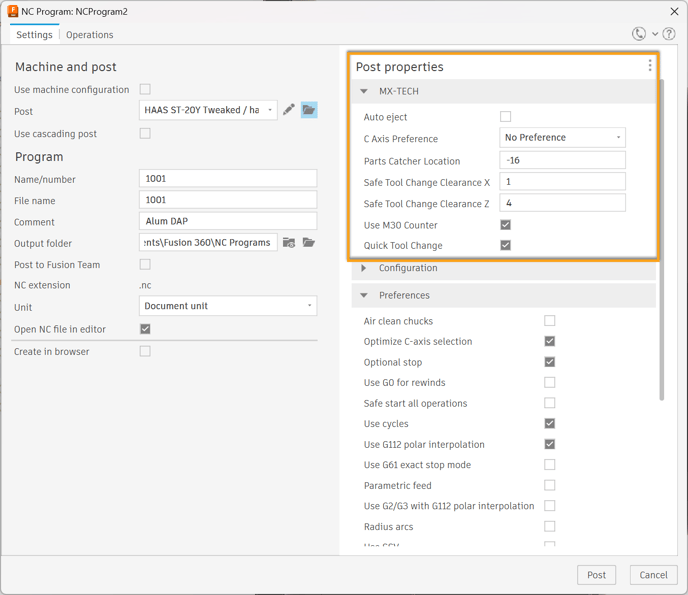

MX-TECH HAAS ST20Y

Post properties

Auto eject:

This will now output the correct Part eject routine

(PART EJECT)

G53 G0 Y0.

G53 X-2.

G53 Z-10.

G53 B0.

M5

M1

M15

M36 (PART CATCHER ON)

G4 P1

B-16. (!!! ADJUST parts catcher values !!!)

G4 P1

M111

G4 P1000

M13

B0. M110

M37 (PART CATCHER OFF )

C Axis Preference:

This changes the direction preference to always be in the negative direction, or positive. Set to "No Preference" if the program will be allowed to switch between positive and negative (this will be efficient)

Parts Catcher Location:

The B axis location in the part eject routine

Safe Tool Change Clearance X and Z:

These are values that will be added to the Unique tool change position in order to add extra clearance away from the part.

Quick Tool Change:

This enables the Unique tool change position. This position is calculated based on the stock material size + the Safe tool change clearance values. It will compare the overall length of the tool being called and the previous tool (tool length below holder + holder length for drills and milling tools ) If the tool being called is longer, then the Z value for that tool will be used.

G0 Z2.35

M9

X4. Y0. Z6. (Unique tool change position)

M135

Use M30 Counter:

Enables the M30 counter and #100 variables

/ IF [ #100 GE 34 ] THEN M30 (M30 Counter is added)

/ #100= #100 + 1

/ M99

![DSI-small-square.png]](https://know.dsi-mfg.com/hs-fs/hubfs/Logos/DSI%20Logos/DSI-small-square.png?height=50&name=DSI-small-square.png)